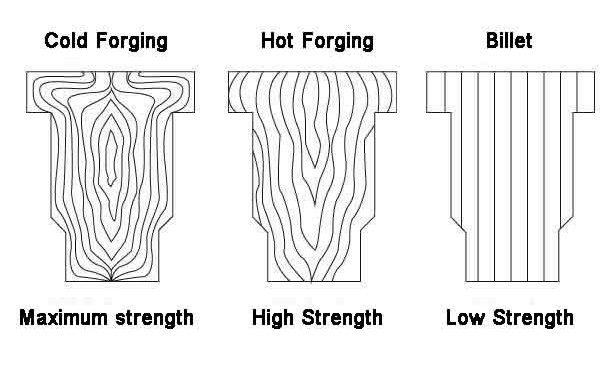

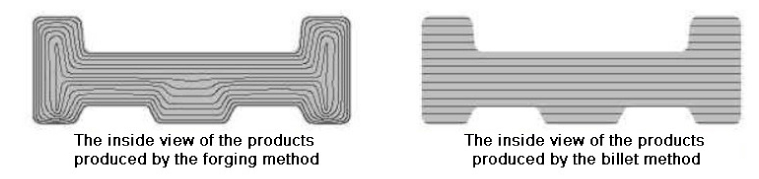

Purpose: To show benefits the products produced by forging production method compared to methods of producing by removing chips from casting, block, profile or plate.

- Superior grain structure and mechanical properties will be provided.

Forged parts have superior grain structure and the best combination of mechanical properties. Aluminum forging production is frequently preferred in defense industry parts that require strength, space and aerospace industry parts and complex shaped parts complications. Products produced by forging reach maximum levels with predictable strength values. While the predicted strength values in the productions made with other methods are in the middle of the given range, the strength is at the upper levels in the forging production method. Strength values are 10% higher than the highest method. As a result of the tests made by us, it has been determined that the yield strength of the forged material is 15% stronger than the rolling direction and 18.5% more than the reverse rolling direction in rolled products. Attached are the relevant test results.

- Processing Time Will Be Shortened, Production Costs Will Be Decreased, and The Speed of Meeting Demands Will Increase.

Since the product obtained as a result of the forging process will be the draft of the final product, the surface to be processed is minimized. Thus, the expenses during processing will be reduced, the time will be shortened and the process will be advantageous. This advantage will reduce processing costs and eliminate material loss during processing.

- Quality of the product will increase and the useful life of the product will increase.

It is not possible to capture the directional crystal structure formed in the products after the forging process in extruded materials. For this reason, forging production method is preferred for quality products. Forgings respond better to heat treatment. Alloy separations that may occur in other methods are minimized in the forging production method.

- There will be no change in the material structure.

Since there will be no change in the chemical composition of the product, the final product will meet all expected quality values.

- Hardness will be provided in the internal structure.

Since the internal structure of the material will be in a directional crystal structure according to the product form, homogenization is achieved in the internal structure of the material. In this process, the increasing hardness value exhibits a homogeneous distribution in the internal structure. The main reason for the increase in the hardness value is that the product is exposed to plastic deformation during the forging process, and in this process, the dislocation density in the structure increases, increasing the hardness of the product.

- Low Cost, Less Chip and Waste.

In the forging method, less material is used compared to the extrusion bar machining method. Forging requires less secondary processing. Some rods and plates as provided may require additional operations such as turning, grinding and polishing to remove the surface.

- A homogeneous grain distribution is ensured thanks to the directional crystal structure.

Crystal structure to be shaped in forging design is obtained. This situation passes by in the material. It offers more good luck and directional properties to tattoo techniques.

- Thanks to the Compressed Structure, the Strength of the Product Will Increase.

The structural reliability achieved in forging has not been achieved in any other mineral processing method. Forging removes defects that occur in other production methods. Perfect microstructure is maintained in fine grains. Forging has no internal gas pockets or voids that can cause unexpected failures under pressure and compression. The forging method is the technique that best provides chemical separation to move the material from the center to the various parts of the forging, which means the structural integrity of the forging products, the fast production rate and the consistent machinability that contributes to the low cost, the most accurate result to hot working and the low control requirement.

- Instead of an assembly group consisting of two or more parts, a more aesthetic product will emerge that can be produced at once.

- Strict Process Control and Inspection Costs Will Be Avoided.

Since the forging production method provides high strength, ductility and resistance properties to the manufactured part, they are produced without the strict process controls and inspection costs found in other production methods. Economically, forged products are produced and processed by automatic methods and are more attractive with their unique high reliability, advanced tolerance capacities and high success levels.

- The piece formed in the forging production method adapts to the shape.

Machined bar and plate are more susceptible to fatigue and stress corrosion because it cuts the base pattern of the machined material. In most cases, it imparts oriented grain structure to the forged part shape and imparts ductility, impact and fatigue strength.

AA 7075 T6 Aluminum Forged Material Sample Tensile Test Result

AA 7075 T6 Aluminum Plate (Reverse Roll Direction) Sample Tensile Test Result

AA 7075 T6 Aluminum Plate (Roll Direction) Sample Tensile Test Result